YOUR PLANT MACHINERY SPECIALISTS

Bringing you reliable spares and a service you can trust for over 32 years.

SPARES > REPAIRS > RELIABILITY

Extend the life of your machine with our reliable spares and repair services.

PARTS FINDER CONTACT US

Diagnostics, Repairs & Reconditioning

WORKSHOP SERVICES CONTACT US

QUALITY AFTERMARKET RUBBER TRACKS

Now available from Plant Parts. Order direct by track size or machine model.

MORE INFORMATION CONTACT US

HASSLE FREE SHIPPING TO EUROPE IS BACK!

Order from Plant Parts - same great prices, same great stock, same great service.

MORE INFORMATION CONTACT US

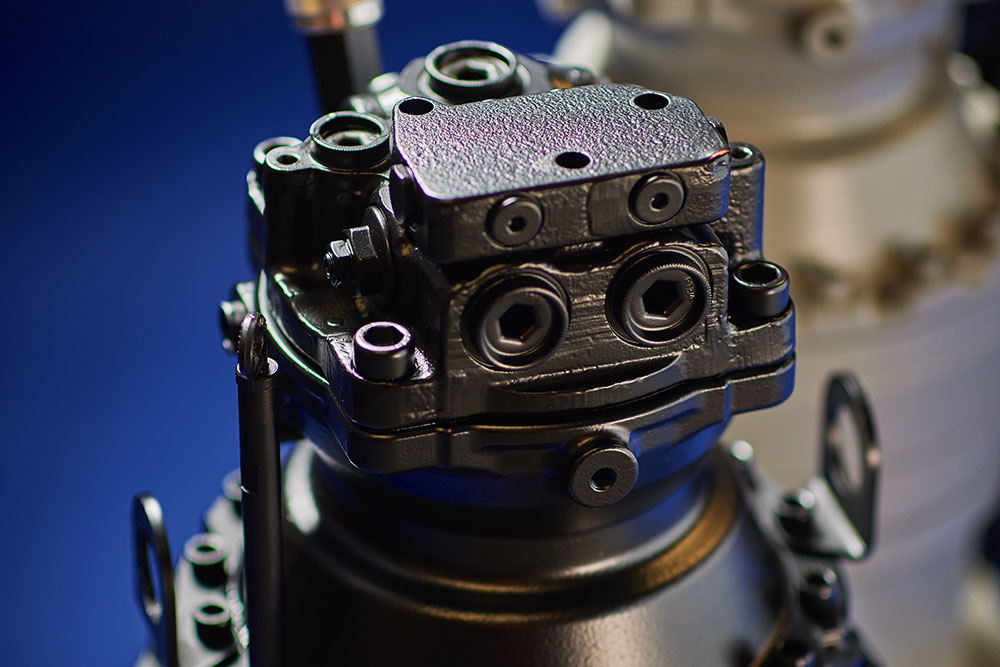

Final Drives and Swing Drives

Established in 1991, Plant Parts is a leading supplier of machinery parts for construction and related industries

We know that time is money when it comes to your equipment so when something goes wrong you need parts fast. With access to over two million parts, a fully stocked warehouse and a state-of-the-art repair workshop, we’ll help get you moving again with high-quality parts you can trust.

From our engineers to our accounts team, we combine expert knowledge with excellent customer service and unparalleled quality. You’ll get the parts you need quickly and efficiently with the peace of mind that they’ll be right first time and built to last.

Search for spares using our parts finders

The service that sets us apart

High availability of parts

Our strong supplier chain and continued stock investment means we have the parts you need when you need them.

Guarantee of performance

We guarantee that the parts we supply will fit and perform to specification, or your money back!

Expert friendly advice

Our friendly team of experts can correctly identify the parts you need, providing you reliable options to maximise your uptime.

Reliable support

Depend on us! We have grown staff, stock and turnover every year since 1991 by providing reliable products and quality support.

Specialist repairs

Our state-of-the-art workshop is the hub for our hydrostatic diagnostics, repair and reconditioning services.

Online parts finders

Our searchable database of over 2 million parts numbers is another reason our team can consistently help you maintain your machine.

Plant Parts supports machine operators in multiple industries including;

Construction, Earthworks, Quarrying, Mining, Landscaping, Forestry, Rail, Demolition, Civil Engineering, Marine & Submarine, Waste Recycling, Material Handling, Wind Power