Cleaning the Slew Ring & the Mounting Structure

Remove extraneous material from supporting structures (including paint residues, rust, welding beads and burr formations).

In doing this ensure that;

- Cleaning material does not penetrate into the Slew Ring.

- Applicable provisions are observed (e.g. manufacturer directions, protection of workers, environmental protection etc …).

- Cleaning solvents that attack the sealing material are not used.

Lubricating the Slew Ring

- Slew Rings are supplied fully lubricated but should be greased again prior to initial operation.

- Inject grease into all grease nipples, one after the other, while rotating the Slew Ring until a bead of grease forms at least on one sealing lip.

Mounting Bolts & Tightening Torques

- Contact your original equipment dealer for fastening hardware and recommended torque specs.

- Before fixing the Slew Ring to the machine frame, ensure the fastening bolts are the exact quality required.

- Do not reuse bolts, nuts, or washers.

- During the fitting we suggest lightly lubricating the bolts.

- We advise using only hardened and tempered flat washers.

- *Do not use any kind of flexible washers*

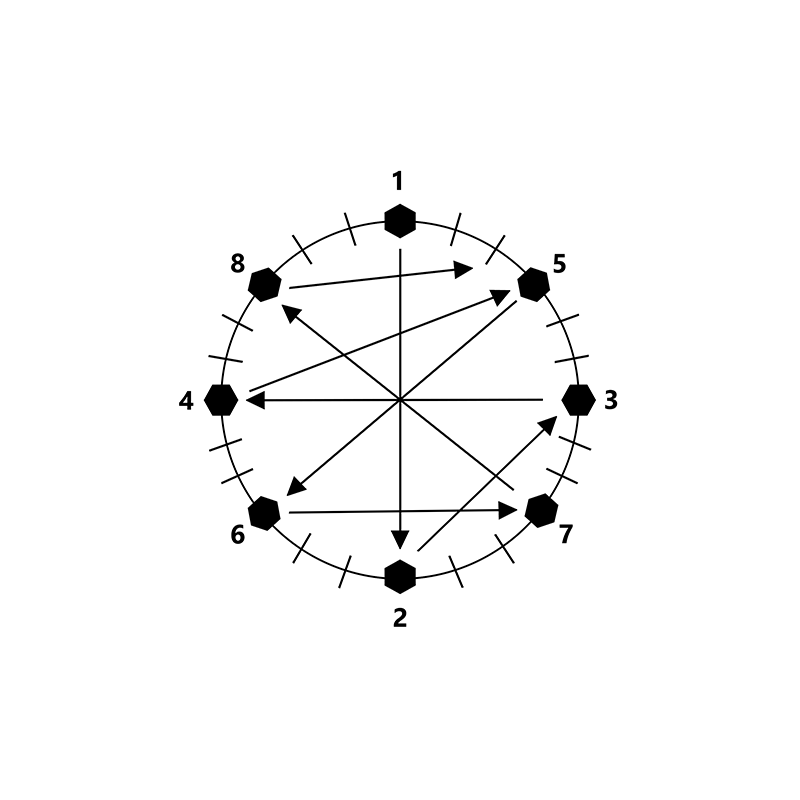

- Please tighten bolts in sequence as indicated by the drawing.

Positioning the Slew Ring

- Determine the main load-carrying zone.

- The soft spot of the Slew Ring is designated by a specific marking on the inner ring – such as ‘S’ or ‘T’ or a line or 2 lines – if unsure, contact supplier for guidance.

- The soft spot is to be placed over the track frame which is 90° to the maximum load zone.

Operating Test

- If the mounting bolts are tightened properly then the Slew Ring should rotate uniformly. Deviations of the mounting structure and the effect of external loads can strongly impact frictional torque.

- Rotate the mounted Slew Ring several times.

- Check whether the Slew Ring runs smoothly without binding.

- Perform further test runs under full load.

*After the operating test, recheck the tightening torques of the mounting bolts.*

Plant Parts stocks a wide variety of Slew Rings for over 9000 machine makes, models and sizes, ranging from 0.8 – 88 ton.

To find the correct Slew Ring for your machine, use our parts finder.

Search for spares using our parts finder

Comments are closed