Spares, Repairs, and Reliability – A Workshop Designed To Deliver

Our state-of-the-art workshop is the hub for our hydrostatic diagnostics, repairs and reconditioning services.

With free UK collection and inward processing authorisation for the EU, our repair centre receives components from all over the world. Our teardown and inspection services are included for free, with repairs or overhauls of gearboxes and hydraulic motors. We are a specialist repair and reconditioning centre for final drives, swing drives and hydrostatic gearboxes.

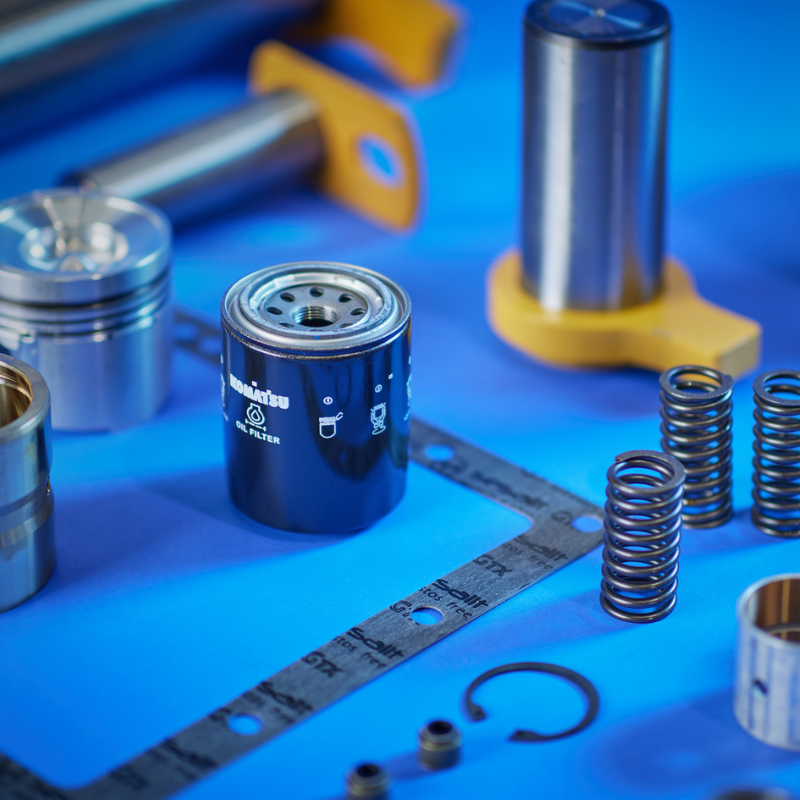

With direct access to millions of parts and detailed technical drawings, we precisely identify faults and find the exact parts to fix them. Replacing only what is necessary and reconditioning parts wherever possible to ensure you get the most cost-effective repair.

“Our Core Exchange Programme saves the customer money whilst contributing to a much greener process of recycling parts to minimise the output into the industry.”

Our Core Exchange Programme

Our Core Exchange Programme saves the customer money whilst contributing to a much greener process of recycling parts to minimise the output into the industry.

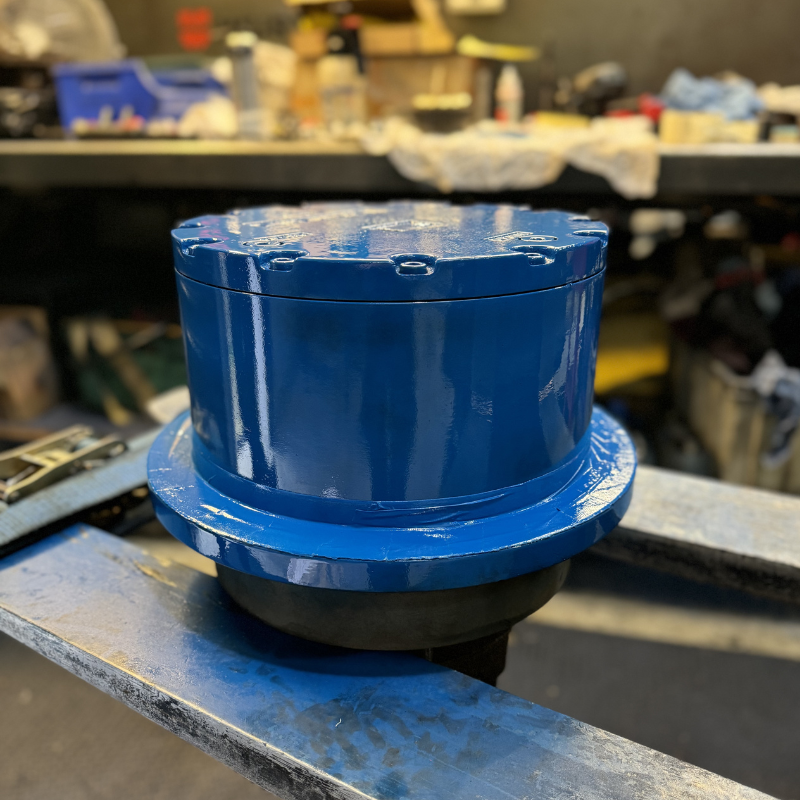

When we sell a new Final Drive, Swing Drive or Hydraulic Pump, where applicable we will offer the customer money off to return and recycle their old component that will be removed from the machine. When the old component is received, it is sent to our workshop to be inspected. If possible, it will be repaired / reconditioned ready to be put back to work and in cases where it cannot be repaired, any good internals will be stripped out to be used in future repairs and the remains responsibly scrapped on site.

This programme not only rewards our customers with discounts on their new purchases but contributes to a more sustainable cycle where nothing is unnecessarily wasted and scrap is responsibly disposed of.