Swing into Summer

Keep cool onsite as the weather heats up

- Warranties

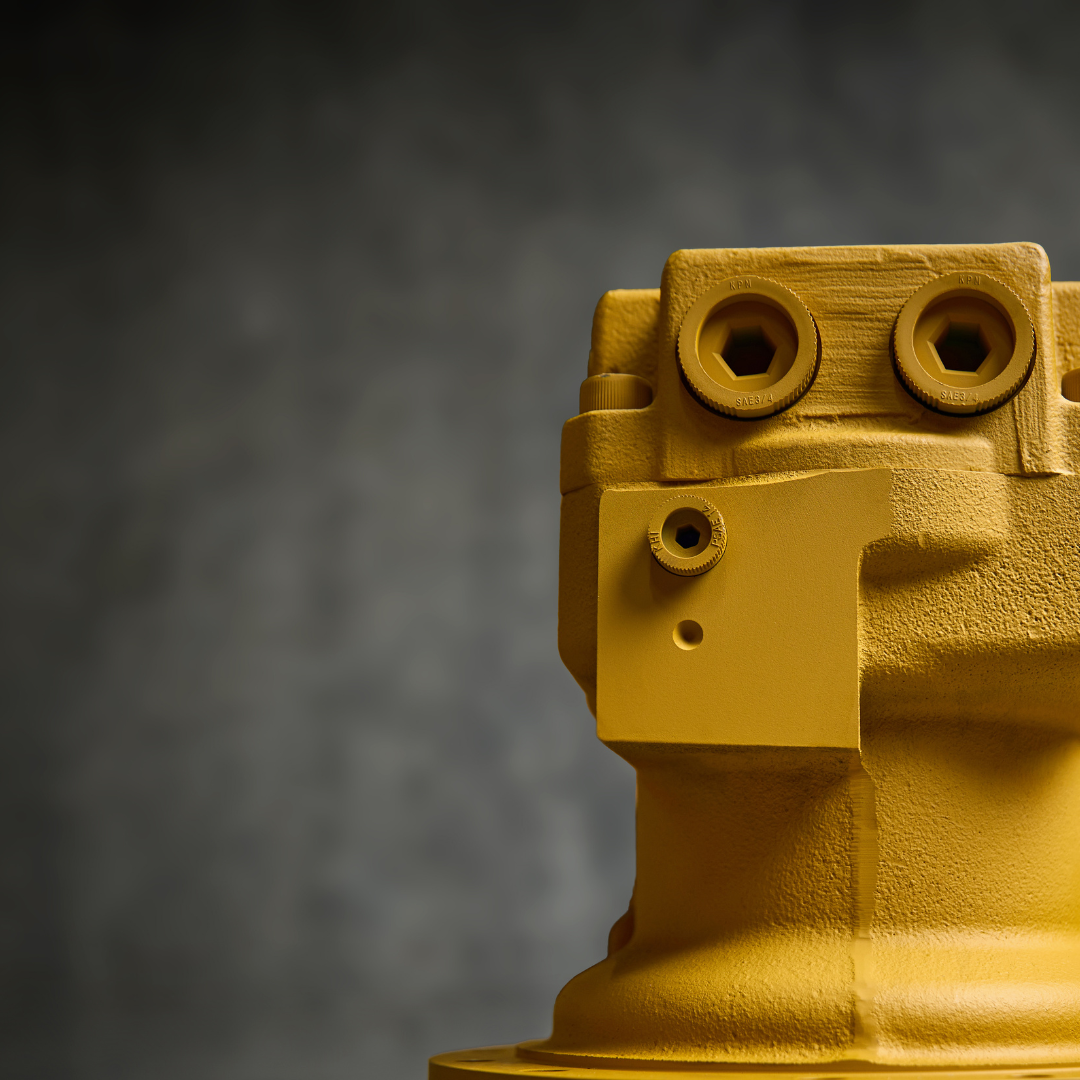

We understand that choosing your supplier for Final Drives can be a tough decision, so let us tell you why you should allow us to resolve the problem!

At Plant Parts we use manufacturers that supply OEMs so you can be sure that our Final Drives are produced using the latest technologies and made from the highest quality materials. We also provide a 2-year warranty service on all of our drives, giving you the peace of mind that we have your back!

- Workshops

With free UK collection* and inward processing authorisation for the EU, our repair centre receives components from all over the world. Our teardown and inspection services are included for free, with repairs or overhauls of gearboxes and hydraulic motors, and we are a specialist repair and reconditioning centre for final drives, swing drives and hydrostatic gearboxes.

With direct access to millions of parts and detailed technical drawings, we precisely identify faults and find the exact parts to fix them, replacing only what is necessary and reconditioning parts wherever possible to ensure you get the most cost-effective repair.

Our workshop is authorised by the manufacturers to deal with warranty services in house allowing us to resolve the problem and return the drive back to you quickly.

- Warehouse

We know that time is money when it comes to your equipment so when something goes wrong you need parts fast. With access to over two million parts, we’ll help get you moving again with high-quality parts you can trust.

Challenges Faced by Heavy Machinery Operators in the UK During Summer: A Focus on Swing Drives

Operating heavy machinery during the summer months in the UK presents a unique set of challenges. These challenges are compounded when considering the specific requirements and maintenance of swing drives, which are crucial components in many heavy machinery types, such as excavators and cranes. This article delves into the various difficulties faced by operators, with a special focus on the issues related to swing drives.

Heat-Related Challenges

- Overheating of Machinery

Engine and Hydraulic System Strain: The high temperatures during summer can lead to overheating of the machinery’s engine and hydraulic systems. Swing drives, which rely heavily on hydraulic power, can suffer from decreased efficiency and increased wear and tear due to the high thermal loads.

Cooling System Efficiency: The cooling systems in heavy machinery must work harder to maintain optimal temperatures. If not properly maintained, cooling systems can fail, leading to breakdowns and costly repairs.

- Lubrication Issues

Viscosity Changes: High temperatures can affect the viscosity of lubricants used in swing drives, reducing their effectiveness. This can lead to increased friction, wear, and potential failure of the swing drive components.

Lubricant Degradation: Prolonged exposure to high temperatures can degrade lubricants, necessitating more frequent changes and increasing maintenance costs.

Maintenance and Durability

- Component Wear and Tear

Increased Maintenance Frequency: Swing drives require regular maintenance to function correctly. In the summer, the frequency of maintenance must increase to address the accelerated wear and tear caused by high temperatures.

Material Fatigue: Prolonged exposure to heat can cause metal components in swing drives to expand and contract, leading to material fatigue and potential failure.

- Dust and Debris

Increased Environmental Debris: Summer conditions often mean

drier, dustier environments, which can lead to more debris entering the machinery. This can clog filters and affect the performance of swing drives.

Sealing and Protection: Ensuring that swing drives and other components are adequately sealed and protected from environmental debris becomes more critical.

Operator Comfort and Safety

- Heat Stress

Operator Well-being: High temperatures can lead to heat stress and fatigue among operators, impacting their ability to work safely and efficiently. Proper hydration, breaks, and cooling measures are essential to maintain operator health.

Protective Gear: Operators need to wear protective gear that balances safety with comfort, which can be challenging in hot weather.

- Visibility and Control

Cabin Temperature: The temperature inside the operator’s cabin can become uncomfortably high, affecting visibility due to fogging or glare on windows and screens.

Ergonomic Control: Ensuring that controls remain ergonomic and easy to use despite the heat is crucial for maintaining operational efficiency.

Improved Materials and Designs

Heat-resistant Materials: Using materials that are more resistant to high temperatures can improve the durability and performance of swing drives.

Operating heavy machinery during the summer in the UK presents several challenges, particularly concerning the maintenance and performance of swing drives. Addressing these challenges requires a combination of vigilant maintenance practices, advanced technological solutions, and consideration of operator comfort and safety. By implementing these measures, operators can ensure that their machinery remains operational and efficient even under the harsh conditions of summer.